6/19/15

Once the foundation spec for the generator was received from AC/DC controls, the foundation could be poured. Poured 18" thick with 3 layers of 5/8" rebar on 12" centers. Four 4" conduits, two 1" conduits, and two 3/4" conduits were stubbed up in pad and run to edge of building. These were buried in a layer of concrete per NEC code. Forms will be stripped on Friday. In about a month the 350kw generator will be placed on this pad.

6/24/15

First of nine trucks arrived on time at 7:00. The steel for the main platform was staged in the area where the winders will go. It took 6 of us 4 hours to unload this container, since all the steel was packed in the bottom of the container with no spacers! Then the crane broke and we could not transfer the steel to the pit. This put is in a bind for the second truck (arrived 3 hours late) as we had no place for that load of steel. For now placing that steel outside. It took 5 of us 4 hours to unload all of the steel out of that truck too. Third truck arrived at 4:00 (instead of scheduled 1:00) and we had it unloaded by 5:30. Long day, but hopefully the worst loads are behind us.

6/24/15

Bill Turpish and Portable Welding Service are hard at work in the basement fabricating the piping network for the Line 7 cooling system.

Close up of the two green pumps which are the circulation pumps for the cooling water thru the furnace and cooler bodies. One will run w/ the other as a back up. In the background you can see the two large blue heat exchangers. Again, dual units for redundancy.

6/25/15

Since no real room was made inside the plant for the 9 truckloads of material, I've had to resort to storing in the "great warehouse under the sky" :-) The red steel is material for the platform for the winders.

Approximately 70 boxes tarped, screwed, and taped to hopefully protect the contents. We'll have to jockey these around a bit when we pick the the back cooling tower in about a week for its' installation at the back of the plant.

More rows of boxes of parts at the back of the parking lot. Reggie took care of tarping the crates last Friday afternoon.

6/29/15

All of the columns for the Big Platform were set, tacked, and most final welded to their base plates today. The beams laying on the floor will be set on the columns beginning Tuesday. We are changing the design slightly to allow removal of the middle and upper platform, if that proves necessary to facilitate furnace rebuilds. This furnace will have to be rebuilt in place.

One of the last tasked completed today was the placing of the furnace shell atop the three furnace frames. The hollow shell weighs 10,000 pounds. The round holes are the locations for the 6 inductors.

Also began setting the columns for the winder platform. The two outer rows are almost complete. Still need to place the columns along the trench down the middle. You can see the steel plates spaced along the trench. These plates will support the middle columns AND serve as supports for the checker plate covers spanning the trench. This is one of several design improvements vs. the Chinese design.

6/30/15

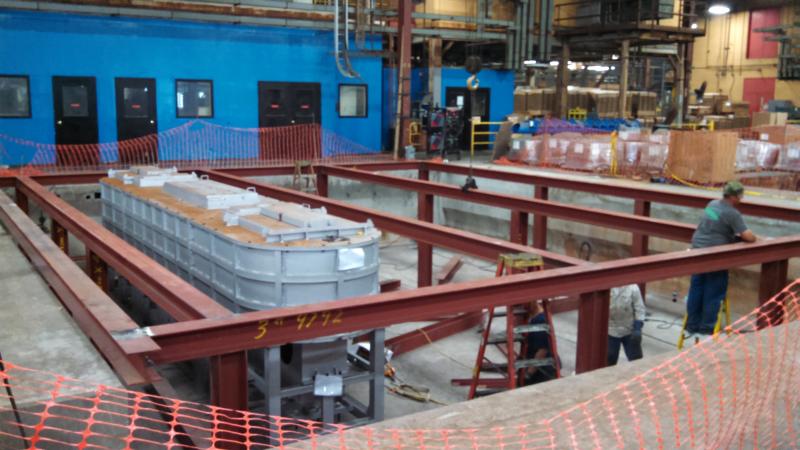

The 7 main beams of the Big Platform were placed and tacked today. There is much better head room in this installation than Line 6, since we were able to dig this pit to as deep as we wanted.

The row of middle columns for the winder platform was completed today. Tomorrow we should start setting horizontal beams on these. Many hours spent solid welding the columns to the base plates today. They were only tacked yesterday.

Piping to the heat exchangers is complete. All of the Line 7 piping in the basement is complete and well ahead of schedule. Portable Welding Service did a very nice job with this.

The pump pipe work is also complete. Pump in the foreground is the overflow pump when in city water cooling emergency mode. The two pumps behind this are the normal mode pumps. Only one of these runs at any one time.

7/1/15

Today the interconnect pieces between the main beams were installed. Next will be the smaller pieces of channel bridging between these.

The winder platform drawings are proving a lot more difficult to translate than the furnace platform. We have it figured out, but the way the steel is configured is going to make assembly more difficult. Turns out quite a few of the columns were supplied short, so we are having to weld plates on the ends to get to the height called out on the drawing. This has been very time consuming. Tomorrow we should begin setting the steel beams on top of the columns. You can see them layout out ready to be installed. All of the columns were solid welded to the base plates today.

7/2/15

All of the smaller pieces of channel have been tacked in between the heavier I beams. About 30% of the I beam connections have been welded solid now.

Several of the horizontal beams of the winder platform were set today. The close spacing between the columns is making tying the columns and beams together a bit of a challenge.

7/6/15

Many channels were installed today along with a lot of the welding of the I-beams together. Unfortunately the short pieces of channel only have one side coped, so we are having to do this.

The north section of beams are in place now, as well as the center row. The beam beside the ladder will form the west part of the opening in the deck the rods will pass thru going to the lower winders.

Oops, the beams down the middle came up short. China cut the beam short, forgetting they needed to add material to account for the cope distance. We will section in a piece of I-beam to fill this gap.

7/7/15

More of the channels going in. This is proving time consuming because only generic lengths of channel were supplied. We are having to cut each to length and cope each end.

The 4th of the 5 beams being installed that runs the length of the winder platform. Their design is making for very difficult installation. The long beam has to be suspended at the correct height, while the smaller pieces (those marked 11# and 2#) are tied in. I would have designed this very differently to make it easier on the guys doing the welding.

7/8 & 7/9

Beams down the middle on the south side were completed and now the beam down the middle on the north side is being installed. Again you can see how the long beam has to be suspended in the air at the correct height while the cross pieces are tacked in, all while keeping everything level both directions. Quite a challenge.

More inter spaced channels continue to be installed (marked 14#, 2592). Staying with the designed 2 between the main beams per the design down the middle of the platform, since this will hold only the water temperature monitoring panels and the main control panel. To the right and left of this, I am changing the design slightly so there will be 3 channels between the main beams. Doing this since on each side is where the cathodes will be moved across the platform.

7/13/15

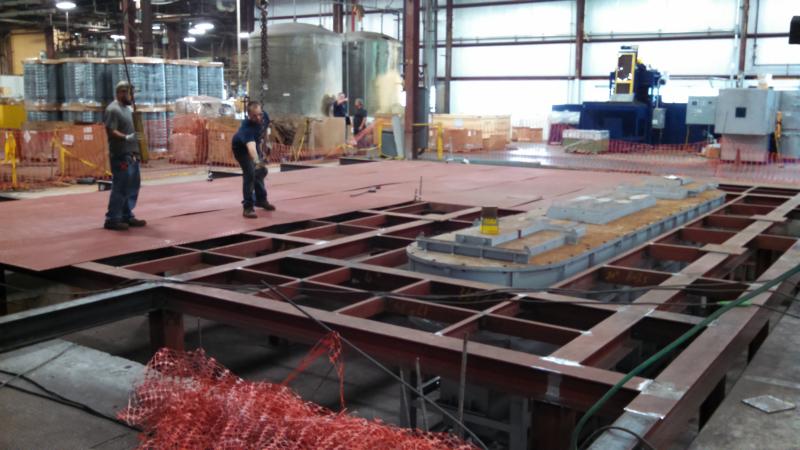

All of the steel structure for the main platform, as shipped, is complete (the red iron). To the right (east) you see the grey beams added, which is the platform extension to over the basement wall. It is here that cathodes and materials to melt will be placed first.

A similiar platform extension has been added to the right (north). This is the beginnings of where the electrical panels will sit. Waiting on additional I-beams to construct this. Ordered lightweight (less expensive) W8 x 10 beams for this instead of the W8 x 24 beams.

7/14/15

Construction of the middle platform has begun. We are building this on the floor so not having to work high in the air for safety reasons.

Meanwhile all of the structural members of the winder platform are in place. Much welding is underway making all the welds 100% solid.

7/15/15

Today we began laying the steel decking. You can see it is a little thin and wavy. This is why we added extra channel iron in the main platform to better support the steel.

7/20/15

A lot of time the last two days has been devoted to straightening and welding down the wavy 1/4" checker plate steel to the top of the Big Platform. It's really starting to look nice. If you look closely you can see Ben standing on the winder platform. Decking of the winder platform has begun. These 3/8" thick sheets are a challenge to handle and shift on the beams! They are using a magnet to offset the weight slightly, so they can shift the plates into final position.

The north extension of the Big Platform is almost complete except for the checker plate span. The two I-beams are what the 8 electrical cabinets and the automatic transfer switch will sit on. We will set these electrical cabinets tomorrow. Fountain Electric will be here on Friday for a pre-construction walk thru of the project. To-date, Fountain has only seen this project on paper, when they were quoting in April. They are scheduled to begin wiring late next week or the first of August.

7/21 & 7/22/15

The extension to the north has been completed and the decking welded down. In the afternoon we placed the transformer cabinets, capacitor cabinet, and the automatic transfer switch (grey cabinet to left end). The hole between the white cabinets is supposed to have a capacitor cabinet, but so far we have not been able to locate it. In the lower right of the photo you can see the additional 8" channel and short pieces laying on the deck ready to weld in for the east extension. We'll be back on this hot and heavy tomorrow. Been focused on the north extension to get the electrical cabinets in place.

All of the winder decking is placed and being welded down now. This is the east end of the winder deck and the large hole is where the 12 strands of copper will pass to the lower 12 winders.

This is a view of the west end of the winder platform. Again all 3/8" plate steel. It is not checker plate steel, so we will see if it is slippery when oily. Heavy checker plate may simply not be available in China.

7/23/15

A great way to wind up the end of week 4 of installation. Using 4 plumb-bobs, we set the main casting machine on top of the middle platform and located this w/ respect to the furnace openings. Tacked in location for now. Just barely had enough room with the crane to get this piece on top!

Start of week 5

7/27/15 & 7/28/15

Began uncrating and setting the winders in their approximate locations on the upper deck. Note the electric motors in each wind table, which should improve wind quality when table winding smaller rod sizes.

Another view of the upper deck with the 6 winders placed.

First piece of handrail installed along the south edge of the Main Platform. On Monday the casting machine was removed and the mounting pads solid welded to the middle platform. Then the casting machine was placed back on the platform. You can see some of the hoses, motors, and water manifolds resting on the furnace. These will all be installed onto the casting machine soon.

7/29/15 & 7/30/15

All the winders have been set and bolted in their correct locations. The swinging gates (Reggie's design) were manufactured by China to Reggie's drawing and have all been welding in place on both sides of the upper platform. Note the frames for the lower winders, which allow coils to be rolled fully out from under the platform. China configures for all coils to be handled by crane. If we commit to all forklift handling, we will need to shorten all of the lower track sections and extend all of the upper track sections.

The cooler body holding fixture (black) has been install to the bottom of the casting machine. The steps have been added and made to be bolt on and off as part of our design change to make the entire casting platform removable to facilitate furnace building. On either side of the steps are the water temperature monitoring cabinets. All of the water from the furnace inductors and coils and all of the cooler bodies passes thru these 2 cabinets, before draining back to the basement water system.

8/3/15

Portable Welding Service fabricated the water "tree" off site and delivered it this morning. This is the pipe network that will switch from process water cooling to city water cooling in the event of power loss or cooling tower failure. This is a critical safety item to assure the furnace is always supplied with sufficient cooling water to the coils and bushings of the 6 inductors.

First of the safety railing is going up around the casting machine platform. The stair set has been fabricated to be removable and you can see the pair of bolts at the top.

The section of handrail at the west end of the winder platform was completed today, completing this end of the winder platform.

8/4/15

I am really looking forward to trying this style limiter which I spec'd for this line. I built one for Line 6 a while back and it was really nice, completely eliminating all speed adjustment requirements by the operator. If we observe this works well, we may order another and upgrade Line 6.

8/5/15

Several days were spent modifying the frames the lower winder/coils will roll out on. They did stick out beyond the structural steel a couple of feet, for picking with a crane. Since we are going to attempt to pick both levels with a forklift to start with, these frame needed to be modified so the forklift could approach the upper coils.

8/6/15

There simply wasn't sufficient room to place a second set of steps in the foundation, but we still felt another means of exiting the pit was required. An inexpensive vertical ladder was purchased and installed in the corner of the platform left open. Safety rails have been added, and a swinging gate from elsewhere in the plant will be repurposed for the end that is still open.

8/10/15

Crane and truck arrived within minutes of each other. Randy McDaniel did well with the trucking arrangements.

Once the tank was centered and set on the concrete pad, the generator head was picked and placed on the vibration isolators on the tank. Had a little trouble getting the bolts in the generator base to line up with the isolators.

Next the enclosure was picked and placed over the generator. Up to now all went smoothly, until we tried to set the muffler brackets and they simply would not fit. At $150/hr for the crane time I had used up the 4 hour minimum, so we sent the crane home and will do whatever is needed to make the brackets fit. Can use a less expensive boom truck for setting the 1000# muffler at a later date.

8/11/15

All of the water piping was completed by mid-August. Our electricians have begun routing wires for the controls.

September

Fountain Electric is in the process of pulling all the large cable to the machine. The yellow, brown, and red wires are all 750 mcm cables. Very hard work pulling these!

The furnace build will take about 2 weeks to complete. A combination of Mr. Hunag, Specialty Foundry, and a PSU temp employee are doing all the ramming work. The complete furnace build is documented on a separate web page. Here is the link to that page. Furnace build.