Click on the small images to go to a full size image.

Here is a picture of an original Stickney fuel pump. After measuring, making a

CAD drawing, and scaling the drawing for shrinkage it was time to prepare a

block of wood.

Clayton, a good friend who is also in the cabinet making business, helped me

with the cutting of pieces of wood, gluing, and clamping them together. Cabinet

wood is all 11/16 thick and it takes quite a few pieces stacked together to make

a part of any appreciable size.

After letting the glue dry for 24 hours we unclamped the parts and this block is

what the fuel pump body will be made from. The wood is Bass wood.

After centering up in a 4 jaw chuck, the square was quickly turned to a round.

Basswood lets you turn 200 thou.

off at a pass! Here the largest diameter has been turned and sanded to final

diameter. I am marking the shoulders for the smaller steps with a standard

parting tool. In fact I just used the parting tool for all the turning too. It

worked as well as any other tool I tried.

The smaller diameters have now been turned and sanded smooth.

Next to the chuck you can see where the parting tool has been driven in as far

as the tool will allow. All that remains is to do a little sanding while it is

still in the lathe to round the corners and create some draft on the shoulders. Once the sanding is done the tail

stock will be moved away and both ends cut off with a saw.

The lathe work is complete. I will just use body

filler instead of leather fillet material to create the blended radii.

Unfortunately I lost several pictures in a hard drive crash that documented the pieces that get added next to this fuel pump body. The fuel inlet and outlet bosses and the mounting bracket were added next. The completed pump body can be seen sitting on the parting board next.

Now that most of the pattern is complete it is time to make the follow board for

this loose pattern. This needs to be done to aid ramming the drag and also to establish the thickness of the core

print. You can see the

scribe lines showing part midline.

Here the finished pattern has been set in the follow board exactly on

centerline. However, there is a big problem! If you were to ram the drag like

this, flip it over, remove the follow board and then try to remove the pattern

the mold would be ruined. Green sand would have been rammed under this flange

preventing the part from being removed.

Here the finished pattern has been set in the follow board exactly on

centerline. However, there is a big problem! If you were to ram the drag like

this, flip it over, remove the follow board and then try to remove the pattern

the mold would be ruined. Green sand would have been rammed under this flange

preventing the part from being removed.

View of the same problem area on the other side. The only solution is to make a

core print and core box to create a no bake core that will form this part of the

mold. This was the most difficult part of the project for me to understand. I

had several conversations with a local foundry and a good friend who is a

pattern maker before it finally sank it. Guess I'm a little slow....

View of the same problem area on the other side. The only solution is to make a

core print and core box to create a no bake core that will form this part of the

mold. This was the most difficult part of the project for me to understand. I

had several conversations with a local foundry and a good friend who is a

pattern maker before it finally sank it. Guess I'm a little slow....

The piece of wood under the

large round boss is the beginning of the core print that will form the fuel pump

body

between the lower edge of the round boss and the follow board.

And a close up of the same. It's hard to tell but the outer edges of the core

have a 5° draft to assure easy removal from the drag mold and from the

core box. The draft has to be in the correct direction to serve both molding

operations.

And a close up of the same. It's hard to tell but the outer edges of the core

have a 5° draft to assure easy removal from the drag mold and from the

core box. The draft has to be in the correct direction to serve both molding

operations.

The core print removed so the inside detail can be seen.

The core print removed so the inside detail can be seen.

Once the core print is accurately made to fit the pattern, the core box can be

built around the core print. Basically a picture frame was built around the core

print fitting tight to it. There is no substitute for a good accurate power

miter saw here! Luckily I had one from doing all the trim work in the house

restoration.

Once the core print is accurately made to fit the pattern, the core box can be

built around the core print. Basically a picture frame was built around the core

print fitting tight to it. There is no substitute for a good accurate power

miter saw here! Luckily I had one from doing all the trim work in the house

restoration.

Here is the core print again. You can see the 5° draft on the outer edges pretty

good in this view. The core would come up out of the core mold pretty good,

except for the negative draft problem on the front edge. This sweeping radius

forms a portion of the round pump body and creates a problem in the core

box.

Here is the core print again. You can see the 5° draft on the outer edges pretty

good in this view. The core would come up out of the core mold pretty good,

except for the negative draft problem on the front edge. This sweeping radius

forms a portion of the round pump body and creates a problem in the core

box.

Again the core print in the core box. You can just see the problem area and how

it would prevent the core from coming out of the mold here.

Again the core print in the core box. You can just see the problem area and how

it would prevent the core from coming out of the mold here.

The only solution is to make a portion of the core box removable to allow the

core to be removed.

The only solution is to make a portion of the core box removable to allow the

core to be removed.

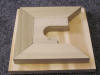

Here is the complete core box with the core print inside. For casting accuracy

there needs to be a good match between the core box and the print.

Here is the complete core box with the core print inside. For casting accuracy

there needs to be a good match between the core box and the print.

With the core print removed the core box is complete. This is the finished box

that will be used to make the no bake core.

With the core print removed the core box is complete. This is the finished box

that will be used to make the no bake core.

To wrap things up the core print needs to be glued to the pump

pattern.

To wrap things up the core print needs to be glued to the pump

pattern.

The final priming and finishing work has been done and the part

numbers added. Stickney put the part number on the back side of the fuel pump

where they can't be seen when it is installed. So that's why I did it too.

The final priming and finishing work has been done and the part

numbers added. Stickney put the part number on the back side of the fuel pump

where they can't be seen when it is installed. So that's why I did it too.