4/6/2015

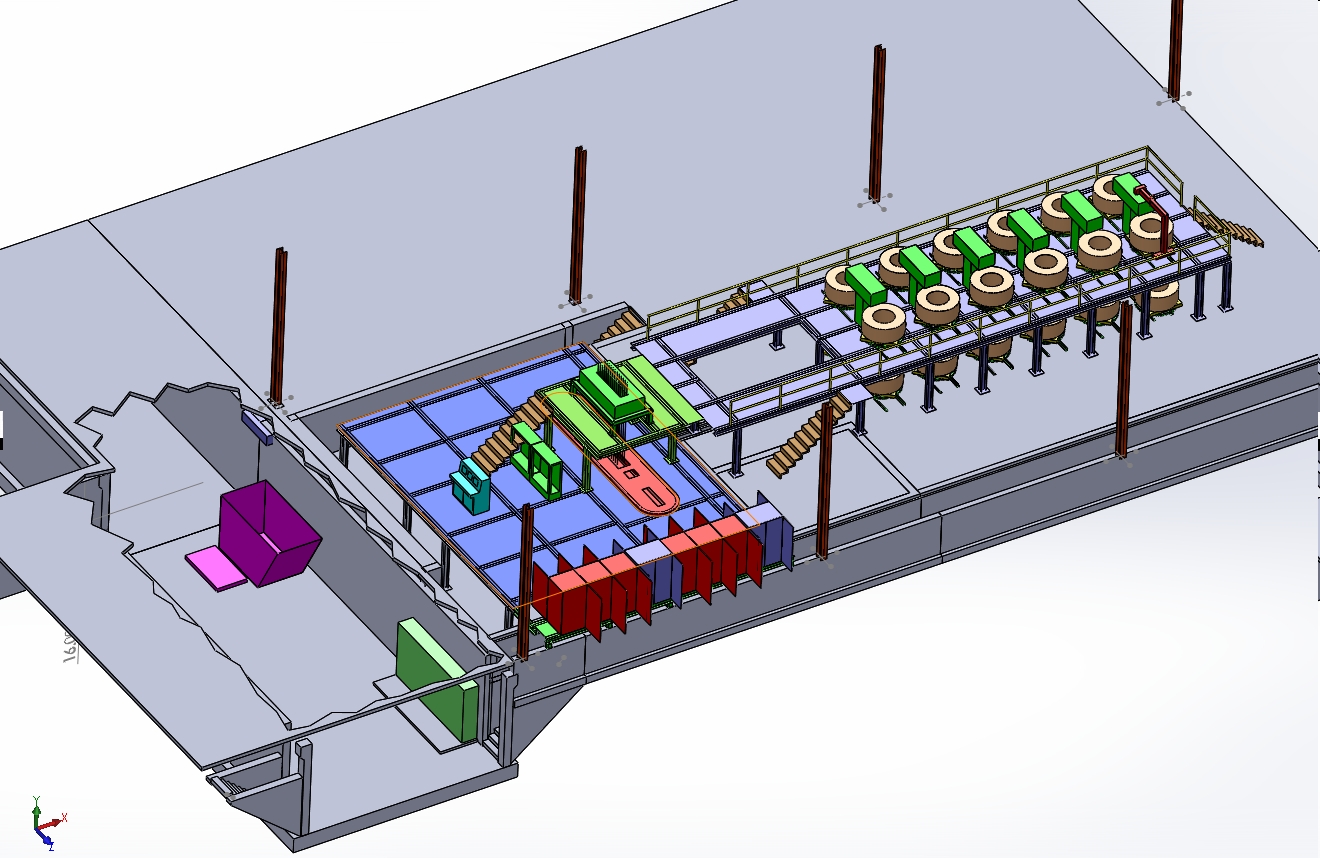

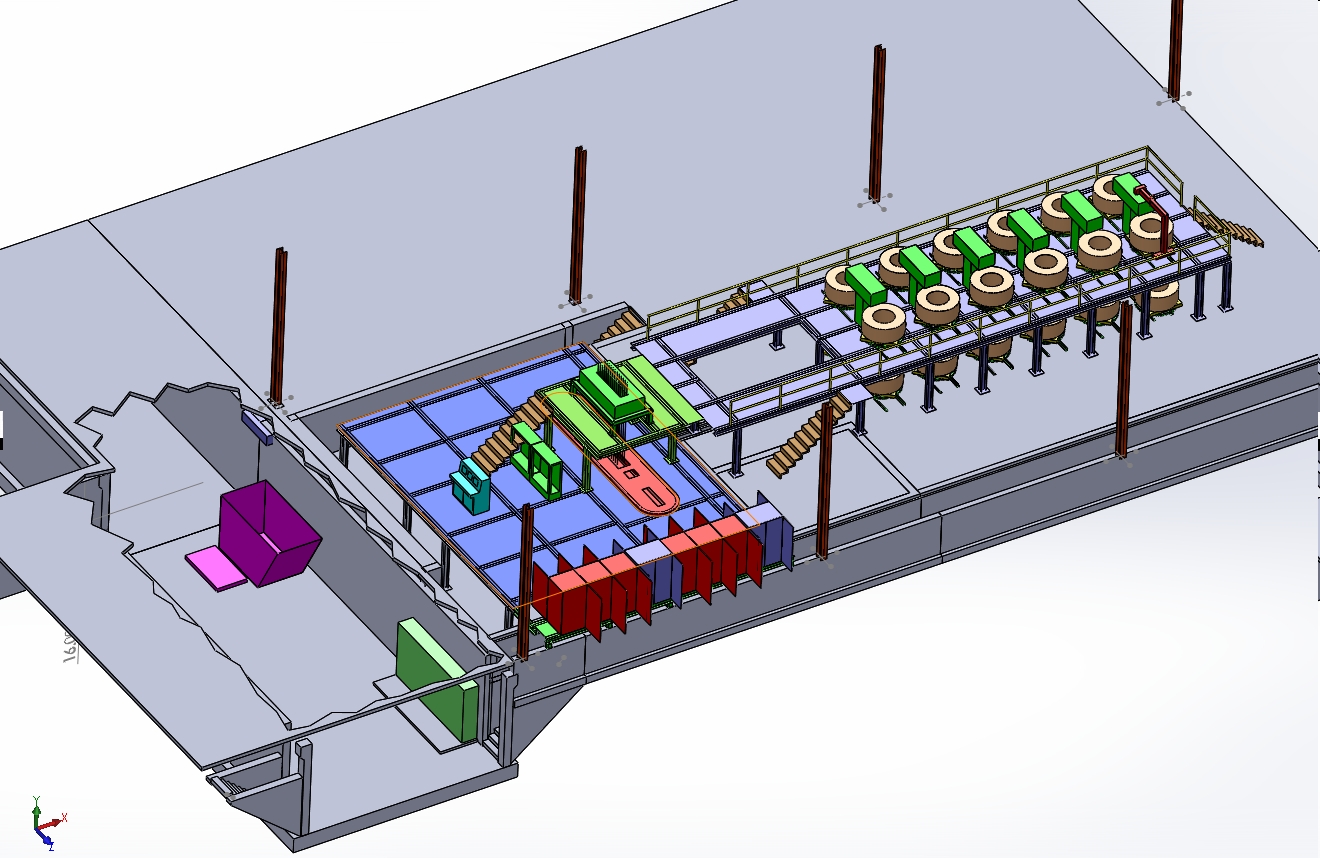

February and March were spent preparing 3D foundation layouts. This isometric shows the new double layer winders, furnace, and basement cutaway.

The main work area almost all cleared out by Joe over the weekend.

Chalk lines snapped and the sawing has begun. This cut is 36" off of the column centerline to avoid the shallow footings at the columns.

At the same time a mass of conduit is being removed to make room for the temporary shoring supports that will be erected 3'6" south of the two columns along the aisle.

The old conduit and wire saved for recycling.

4/7/15

Jackhammer work beginning to the original section of the floor. In the foreground you can the lighter, newer concrete that caps the old pit. Where the old and new meet is a long wall. Calvin is removing the old floor so he can get to the side of this wall to begin its' removal. Once the cap is removed, he'll excavate dirt and create a ramp down to work this wall.

4/8/15

Jackhammering has gone on all day. All of the original floor has been broken and removed (dirt area on the right), and now Calvin is breaking the cap over the old Z2/L2 pit installed a couple of years ago.

4/9/15

Running the track hoe and a pair of skid steers, Calvin's crew removed the cap of concrete broken up yesterday and most of the gravel from the Zone2/Line2 pit.

4/10/15

Once the gravel was removed from the old pit, then excavation of dirt to the south of the wall began. Meanwhile they were saw cutting the wall on the far side in 6' wide sections so that Calvin could jackhammer easier. We knew about the pipes and Calvin has carefully worked around them. The one in the front is for a floor level drain, the one on the back a cleanout for the drains in the pit behind the pipes. We want to preserve these and use as a floor drain for the new pit. These pipes go down to a -11 foot elevation, so plenty deep enough to drain the new pit.

4/13/15

Over the weekend our maintenance guys Marty and David cut all the welds loose and removed the checker plate covers. Then the old tin line cooling water pipes were removed, along with hydraulic lines and an air line. Now Calvin can begin jack hammering all of this trench out.

4/14/15

CP Metalcrafter installing the temporary shoring columns on the two building columns that will have their footings compromised. They are spaced per Mark Thompson specification.

Much work spent Monday and today excavating dirt and the old tin trench so that so that the ramp can be made the full width of the pit allowing full access to the wall being jack hammered out. There is MUCH more dirt excavation required for this pit than the Line 6 pit.

4/15/15 and 4/16/15

Dirt was excavated from against the wall of the basement today, revealing the strange wall and slab construction. This was all well documented on the Chase drawings, so we knew right where to cut with Calvin's small diameter saws. You can see the cut made in the floor slab at the point where the floor was about 8" thick. This let us get the floor demo'd to be able to excavate this dirt. The remaining piece of the slab that ties into the wall is 24" thick at the thickest point. This will require a bigger saw to clean up this edge. More on that later.

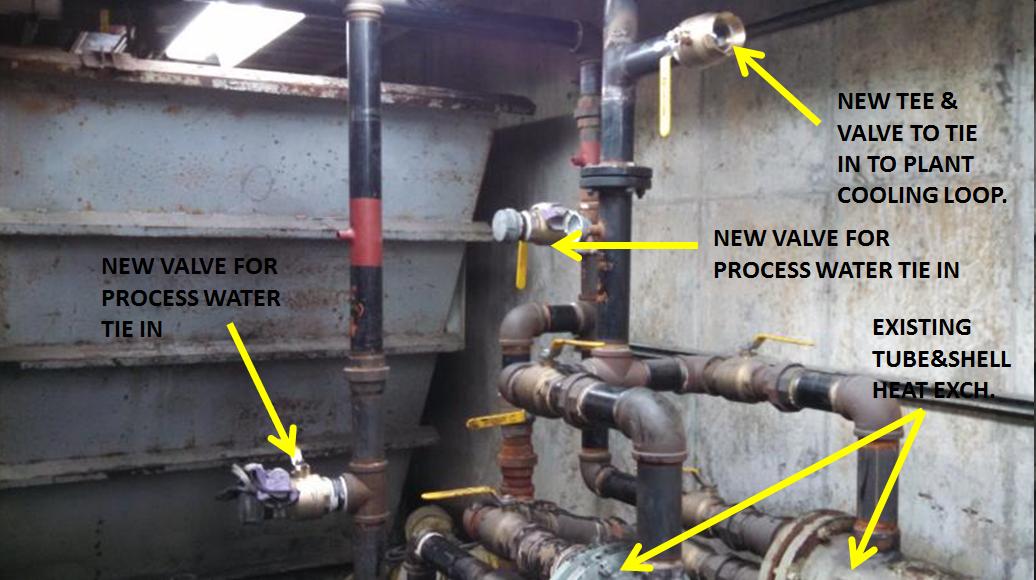

At the same time on Line 6, David Mathis was busy making the tie ins to the process and building water cooling loops for a future plate heat exchanger. I decided to just let the existing tube and shell heat exchanger be the back up heat exchanger in the future when we add the plate heat exchanger. Much simpler, much less expensive. Here you see 3 of the 4 ties in made while we had water turned off to Line 6 in the basement.

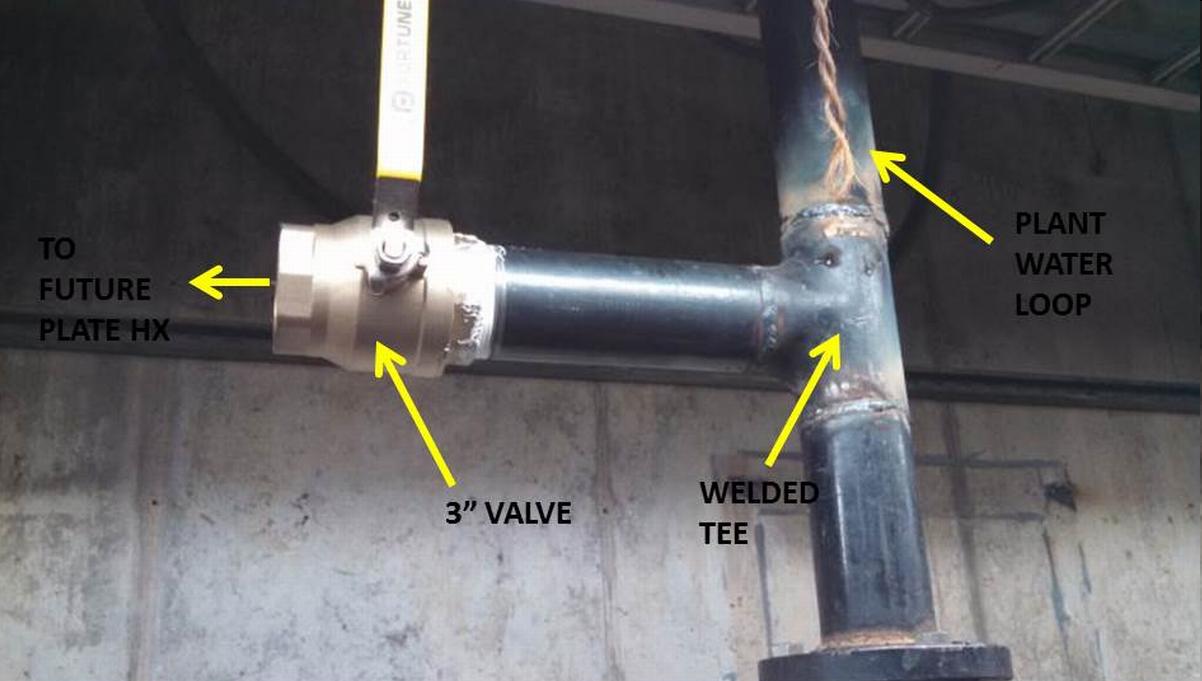

And the 4th tie in. This is the other tie in to the plant cooling loop.

4/17/15

Here you can see all of the original pit wall has been removed. Now Calvin is continuing to work on removal of the floor of the annealer pit. It is a full 12" thick and proving quite time consuming to remove. Very slow progress yesterday and today on this phase.

As you read earlier, addressing the strange shaped wall and slab tie in was going to take a different approach, since the slab is up to 24" thick where the wall and slab meet. Calvin rented this HUGE concrete saw to try and get thru as much of the floor here to make this edge as clean as possible.

We are trying to get as close to the widest part of the west side of the basement wall as we can to make this edge as clean as possible. It's rare to deal with concrete this thick. The saw is a $50,000 piece of equipment!

4/20/15 & 4/21/15

Finally all of the annealer pit floor has been excavated. Dirt excavation to the correct depth continues.

View looking due north.

And view looking south. Calvin hasn't quite excavated dirt all the way to the column footing at the top left of the photo.

No work on 4/22, 4/23, 4/24. Since it has FINALLY quit raining for a few days, Calvin had some other jobs he had to work on. This was agreed to ahead of beginning this job.

4/27/15

The last of the wall from the old Zone 2 pit is gone. It wasn't even doweled to the basement wall, making removal easy. The last of the dirt is being excavated in the east half of the pit to the -88" depth.

4/28/15

Dirt compacted at the correct elevation and a layer of rock placed. 6mil plastic will go on next, along with forms, and rebar matting. The hand digging is finding the other drain line. I'm going to put both drain lines in service, just in case one ever gets clogged.

4/29/15

Pouring of the east floor of the pit has begun. Note the vapor barrier and rebar. The missing form in the foreground is left out so Calvin could drive on this part of the dirt to reach to dump the concrete. Now the rebar is being added and the form added while the second truck of concrete is in route.

The entire east half of the pit floor is now poured. Now to wait and run the rotary finisher thru the afternoon.

4/30 and 5/1

The water you see on the freshly poured floor is where a saw cut was made to establish expansion joint, otherwise a random crack might develop. To the right you see final excavation of the west half of the pit. The trenches are the footings for the furnace.

Another view of the same.

5/4/15

Final excavation of the west half of the pit is nearly complete. You can see the white rock in the dirt walls that has hampered progress. Thankfully Calvin didn't put a rock clause in his proposal, so we won't get dinged for the extra work this imposed. The plastic and multiple rebar layers has begun in the footings area.

This area being excavated is where the stairs will be going down into the pit. You can really see the extent of the rock here.

5/5/15

The footings area has all the rebar layers complete.

You may ask why a floor under the stairs? It is easier to just pour wide than individual footings under each wall. The back (where the stick is propped) will not have a wall. Just left and right of the stairs will have walls.

5/6/15

The west half of the floor and footings for furnace were poured today. The last of the concrete going in about 12:30. Herb will be running the rotary finisher until about 5:00.

5/7/15

Rebar for the walls is being tied in to the floor rebar. There is a double mat of rebar in these 12" walls. There will be several days of this work.

5/8/15

Dual mats of rebar in place, it is time to begin placing the wall sections. This will form the south wall of the pit.

This will form the west wall and steps area.

5/11 & 5/12/15

The extensive wall bracing is to contain the tremendous hydraulic forces of the wet concrete during the pour. Bracing at the bottom, midpoint, and top of the wall forms is complete on the left wall (south wall). Bracing on the west wall has just begun.

Now most of the bracing of the west wall is complete.

5/13/15

Pouring of the walls began at 8:30. It was poured in 6" lifts over the course of the day, with the final pour about 3:00. This allows the concrete on the bottom to partially cure as you work up, and helps keep some of the hydraulic pressure off the wall.

All done. Hard to see them, but we installed 12" deep hand rail pockets on 6 foot intervals down the length of this wall and around the stairwell opening. We will probably just extend the main platform over this wall anyway, but in the event we don't, we will have pockets to place safety rails in place.

5/14/15 & 5/15/15

The last of the old Zone 2 pit has been filled with broken up concrete floor and gravel, the plastic and rebar mat placed, and this is ready for concrete. In the background you see the trench (for the winders) being saw cut. This extends 758" to the west.

The bottom of the trench has been poured at -10" elevation. The stobs of rebar will tie the walls of the trench to the base just poured. In the background you can see Herb finishing the cap just poured on top of the old Zone 2 pit.

5/18 & 5/19

Meanwhile a couple of guys have spend several days stripping the forms, leaving nice clean walls.

This is the first part of the form that will form the walls of the trench. On the floor to the right are the second part of the forms that will sit atop the forms already in the pit. Since the columns of the winder platform will sit on this trench, I wanted steel strips to weld the column footings to. These steel strips are seen attached to the wooden form underneath. The L anchors welded to the bottom of the steel strips will afix the steel to the concrete walls.

5/20/15

The second form of the trench has been positioned. This second form holds the steel runners at the correct elevation.

The beginnings of the forms for the steps. Formed at 8" rise x 11" run, a good comfortable rise/run ratio.

This small form is to cleanup where we undercut the floor of the trench and to blend it nicely to the floor.

Concrete was poured a little loose, so that when vibrated would flow easily up under the steel and fully support the steel runners. These steel runners are where the middle columns of the winder platform will bear.

All poured and finished.

Steps have just been poured and Herb is starting the finish work. Broom finish for traction will be done. This is the last of the concrete pouring.

5/21 & 5/22/15